Light Storage Intelligent Prefabricated Modular Residential Building

Brand Dichu Equipment Technology (Shandong) Co., Ltd.

Product origin Weifang, China

Delivery time 15-20 days (can be expedited)

Supply capacity 1 million square meters

Product highlights of photovoltaic storage intelligent prefabricated modular housing

1. Energy integration of photovoltaic storage intelligent prefabricated modular housing: combining green design concepts, adapting solar panels and energy storage equipment, realizing the use of clean energy, and further reducing energy consumption.

2. Green environmental protection and energy-saving design of photovoltaic storage intelligent prefabricated modular housing

-Environmentally friendly materials: using polycarbonate endurance panels, fireproof rock wool, galvanized steel frames and other materials, with high strength and low pollution characteristics, some panels meet Class A fire protection standards, reducing fire risks.

Energy saving and insulation: The wall is filled with insulation materials (such as polyurethane and rock wool), with airtight design, warm in winter and cool in summer, reducing air conditioning energy consumption; modular production reduces on-site construction pollution.

Recycling: It can be disassembled and reused many times, with a lifespan of 8-10 years, reducing the generation of construction waste, and conforming to the concept of sustainable development.

3. Structural safety and adaptability of photovoltaic storage intelligent prefabricated modular housing

Strong disaster resistance: The steel-wood/light steel structure is stable, with outstanding earthquake and wind resistance, which can withstand natural disasters such as typhoons and earthquakes, and ensure residential safety.

Fireproof and moisture-proof: Some sandwich panels have a fireproof grade of A, and the core material is waterproof and moisture-proof, suitable for humid or rainy environments.

Wide terrain adaptability: It can be built on complex terrains such as hillsides, deserts, and riverbanks, without occupying permanent land resources, and is suitable for temporary or semi-permanent building needs.

4. Flexible construction and rapid delivery of photovoltaic smart prefabricated modular housing

Modular design: Standardized components are prefabricated in the factory, assembled on site, and ready to use.

Flexible space customization: Customization is supported, the interior can be freely partitioned, and the position of doors and windows can be adjusted arbitrarily to meet the diverse needs of office, residence, warehousing, etc.

Convenient mobility: The overall detachable transportation is suitable for frequent relocation scenarios (such as construction sites, temporary exhibitions), reducing transportation costs.

5. The combination of economy and aesthetics of photovoltaic smart prefabricated modular housing

Cost advantage: Compared with traditional buildings, the cost is 30%-50% lower, and no long-term maintenance is required, with a high return on investment.

Through intelligent control, application of environmentally friendly materials, efficient energy management and modular construction technology, the Green Intelligent Prefab House of Guangchu has achieved a comprehensive upgrade in safety, energy saving, flexibility and economy. It is especially suitable for temporary offices, emergency housing, eco-tourism and other fields.

1.Product name: Solar energy storage intelligent prefabricated modular housing

6.16/7.44 *3.64Single/double-storey activity room material list

part name | Material | Single layer(mm) | Double Layer(mm) | Three-layer(mm) | |

Frame

Frame | Front wall column | Double 80#C steel | 1.6(±0.1) | 1.8(±0.1) |

|

Middle column | Double 80#C steel |

|

|

| |

Rear column | Double 80#C steel | 1.6(±0.1) | 1.8(±0.1) |

| |

Floor beam | 80#C steel |

| 1.8(±0.1) |

| |

Geotrough | 80#C steel | 1.8(±0.1) | |||

Roof beam | 80#C steel | 1.8(±0.1) | |||

Floor purlin | 80#C steel | 1.8(±0.1) | |||

Roof purlin | 80#C steel | 1.8(±0.1) | |||

Corridor bracket | 80#C steel | 1.8(±0.1) | |||

stairs | Steel Stairs | 1.8(±0.1) | |||

Walkway board | Checkered Plate | 1.8(±0.1) | |||

Floor (red/white) | Multilayer sandwich panel | 1.8(±0.1) | |||

Board

Material

| Roofing | 50# rock wool board | 030/030(±0.01)Weighted cotton | ||

Wall panels | 50# rock wool board | 030/030(±0.01)Weighted cotton/single film | |||

Door with frame (push handle lock) | (ordinary) | 04 Door |

| ||

Plastic steel window (three tracks) | (Normal/Anti-theft) | Winning bid for anti-theft windows |

| ||

|

|

| |||

5. Product details pictures and description

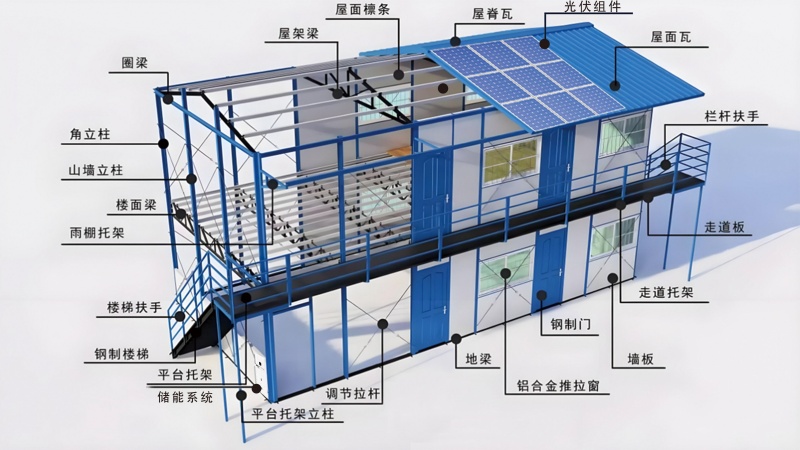

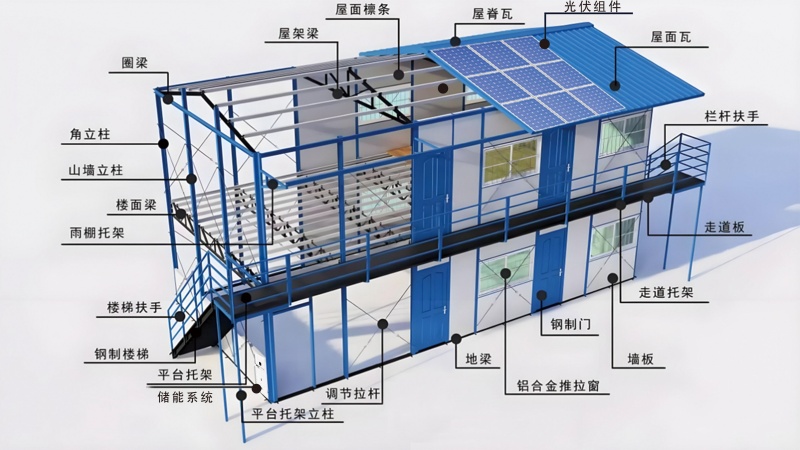

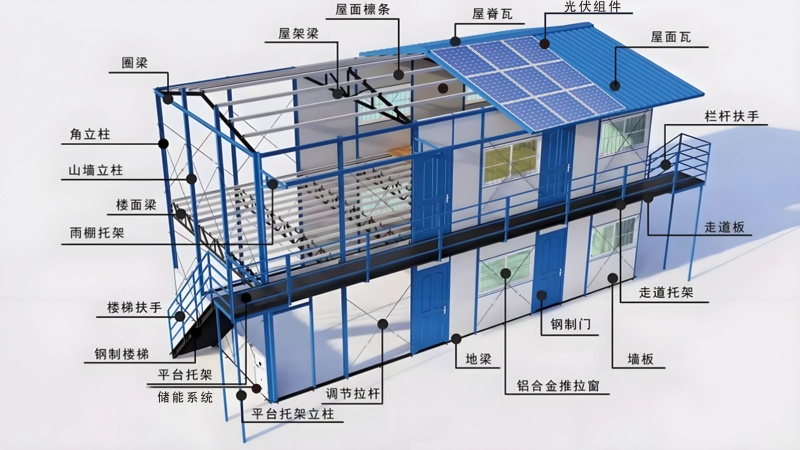

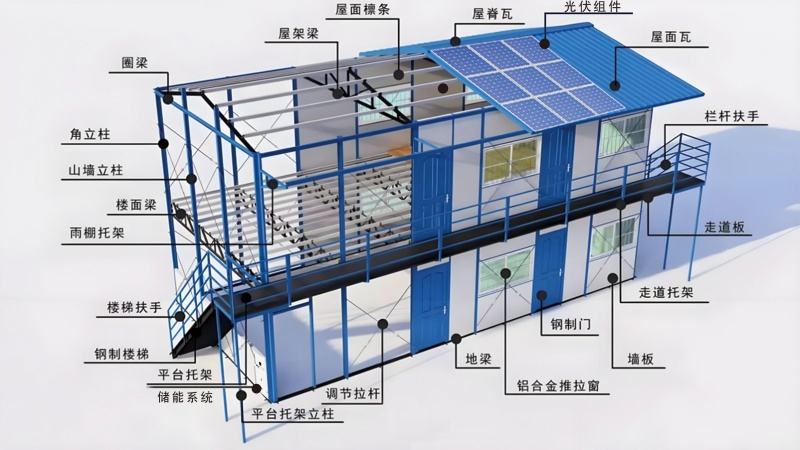

The prefabricated house mainly has light steel frame structure and color steel sandwich panel structure. The following is a specific description:

Light steel frame structure

Steel column: usually C-shaped steel or square steel pipe is used. It is the main vertical load-bearing component of the prefabricated house. It is arranged at a certain interval along the four corners of the prefabricated house and the length of the wall. The weight of the prefabricated house is transferred to the foundation. It can withstand large vertical and horizontal loads to ensure the stability of the structure.

Steel beam: Generally, C-shaped steel or H-shaped steel is used as a horizontal load-bearing component, which is placed on the steel column to bear the load of the roof and floor and transfer the load to the steel column.

Purlin: Mostly C-shaped steel or Z-shaped steel, arranged vertically with the steel beam, used to support the roof color steel sandwich panel or roof panel, and evenly transfer the roof load to the steel beam. The spacing is determined according to the specifications and load requirements of the roof panel.

Support system: includes horizontal support and vertical support, usually made of round steel or angle steel. Horizontal support is set in the roof or floor plane to enhance the horizontal rigidity and integrity of the structure and resist horizontal force; vertical support is set along the column height to improve the stability of the steel column and enhance the structure's ability to resist lateral force.

Color steel sandwich panel structure

Color steel panel: made of color coated steel plate, with rich colors and good decorative properties, high strength and good durability, can protect the core material in the middle, and withstand external wind loads, snow loads, etc.

Core material: polystyrene, rock wool, polyurethane, etc. Polystyrene core material is light, good in thermal insulation but poor in fire resistance; rock wool core material has good fire resistance, thermal insulation and sound insulation; polyurethane core material has excellent thermal insulation, waterproofness and strength.

Connection method: the boards are usually connected by tongue-and-groove or concealed-button connection. The tongue-and-groove connection is that the edges of the boards have concave and convex tongue-and-groove, which are plugged into each other during installation and then sealed with sealant, which is waterproof and has good integrity; the concealed-button connection is to fix the board to the frame through special fasteners, which has a neat appearance and is easy to install.

The ground structure of the prefabricated house often uses a concrete foundation or a steel frame floor, and the door and window structure generally uses plastic steel doors and windows or color steel sandwich panel doors to meet the use function and the stability of the overall structure.

。

Monocrystalline silicon photovoltaic panel is an efficient and stable solar power generation equipment, which is made of monocrystalline silicon material and is widely used in photovoltaic power generation systems. Its core advantages lie in high photoelectric conversion efficiency, excellent low light performance and long life, making it an important part of modern clean energy.

The energy storage system we launched is an intelligent energy solution that integrates lithium iron phosphate batteries and high-performance inverters. It is designed for home, industrial and commercial, microgrids, and source-grid-load-storage scenarios. The light energy storage system adopts a modular design, supports stacking and wall-mounted installation, and is flexible to adapt to different space requirements. It also has the characteristics of efficient energy conversion, long life, high safety, and intelligent management.

Product Features

High-efficiency energy conversion

Using high-quality lithium iron phosphate batteries, the cycle life exceeds 6,000 times and the service life is more than 10 years.

The inverter has a maximum conversion efficiency of more than 98% and supports fast charging and discharging.

Intelligent management system

The solar storage intelligent prefabricated house is equipped with an advanced battery management system (BMS), which monitors the battery status in real time and provides multiple protections such as overvoltage, undervoltage, and overtemperature. It supports multiple communication protocols such as RS485 and CAN, and can be seamlessly integrated with mainstream inverters.

High safety

Lithium iron phosphate batteries have excellent thermal stability and will not cause thermal runaway even under extreme conditions.

The inverter has a complete fault protection function to ensure the safe operation of the system.

Application scenarios

Home energy storage

Combined with solar panels, store excess energy during the day and use it at night or during power outages.

Provide backup power to ensure that basic household appliances operate normally during power outages.

Industrial and commercial energy storage

Charge when electricity prices are low and discharge when electricity prices are high to reduce electricity costs.

Improve energy efficiency and reduce dependence on the power grid.

Microgrid

Supports off-grid and grid-connected operation to improve energy self-sufficiency.

Optimizes the use of distributed energy and reduces the instability of renewable energy generation.

Source-grid-load-storage

Smooths power fluctuations on the power generation side and the user side to improve the quality of the power grid.

Achieves primary and secondary frequency regulation control to improve the stability of the power grid