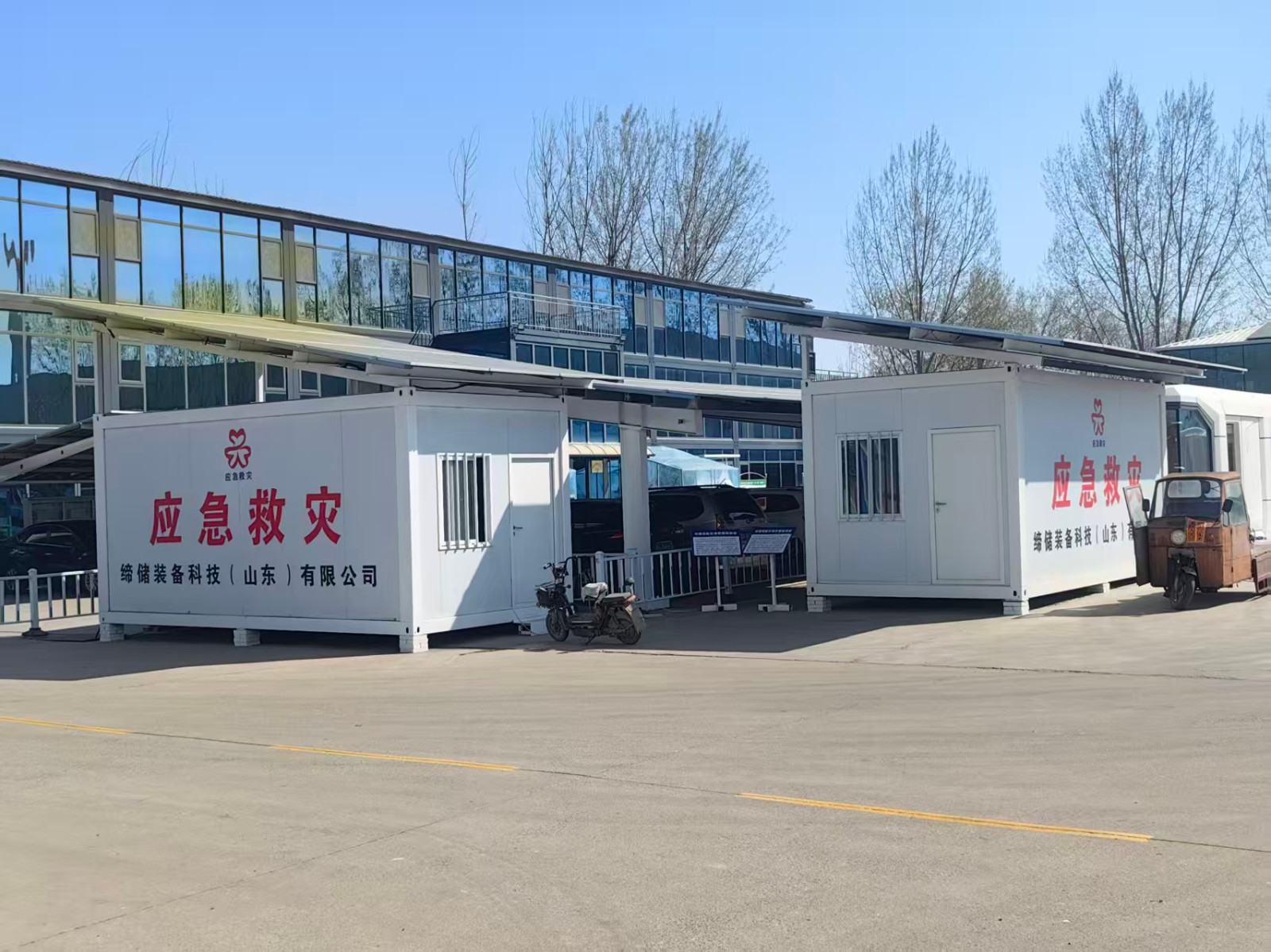

Mobile home factory production

#Introduction to Assembly of Finished Boxes for Xinguang Integrated Housing

The finished product box of Xinguang integrated house is equipped with * * integrated energy storage system * *, adopting standardized and modular design, with the characteristics of quick assembly, easy operation, and no need for professional large-scale equipment. It can achieve rapid landing and production, meeting the needs of multiple scenarios such as residential, office, campsite, cultural and tourism supporting facilities.

##1、 Preparation before assembly

1. * * Site survey and leveling**

Confirm the levelness of the installation site, remove debris, and make proper drainage plans; If it is an overhead installation, precast concrete piers or steel structure foundations in advance.

2. * * Material inventory**

Check the main body of the finished box, connecting accessories (bolts, sealing strips), photovoltaic system components (photovoltaic panels, energy storage batteries, inverters), door and window accessories, etc. one by one according to the list to ensure that there are no missing or damaged parts.

3. * * Tool preparation**

Equipped with commonly used tools such as wrenches, screwdrivers, drills, and level gauges, there is no need for large lifting equipment (small finished boxes can be manually handled with simple lifting equipment).

##2、 Core assembly steps

1. * * Finished product box is fixed in place**

-Manually or mechanically lift the finished product box to the designated position, and calibrate the levelness and verticality of the box body with a level.

-Fix the box and base with anchor bolts. When multiple boxes are spliced, align the box splicing positions, tighten them with connecting bolts, and fill the gaps with sealing strips to ensure waterproof sealing.

2. Installation of doors, windows, and internal facilities**

-Check the firmness of pre installed doors and windows, and reinforce them if necessary; Install basic circuits such as indoor lighting and sockets (with reserved interfaces for optical storage systems).

-Assemble interior components such as flooring, wall panels, and ceilings according to requirements to quickly complete space creation.

3. Integrated optical storage system**

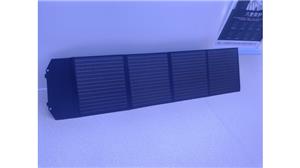

-Photovoltaic panel installation: Fix the photovoltaic panel on the top of the box with a bracket, adjust the angle to maximize the lighting efficiency.

-Energy storage and inverter connection: Connect energy storage batteries, inverters with photovoltaic panels, and indoor circuits to complete energy conversion and storage; The system supports both grid connected and off grid modes, and can be powered on with just one click.

4. * * Acceptance and debugging**

-Check the sealing of the box (rain test) and structural stability; Debug the light storage system and confirm that the power generation, storage, and supply functions are normal.

-Clean up the installation site, and the finished product can be put into use.

##3、 Assembly advantages

1. * * Efficient and fast * *: Single box assembly only takes * * 2-4 hours * *, and multi box splicing can be completed within 1 day, far faster than traditional construction.

2. * * Easy to operate * *: No need for a professional construction team, ordinary workers can get started with simple training.

3. * * Flexible adaptation * *: Supports single box independent use or multiple box combination expansion, and the optical storage system can be selected as needed to meet different electricity needs.

The finished product box of Xinguang integrated house is equipped with * * integrated energy storage system * *, adopting standardized and modular design, with the characteristics of quick assembly, easy operation, and no need for professional large-scale equipment. It can achieve rapid landing and production, meeting the needs of multiple scenarios such as residential, office, campsite, cultural and tourism supporting facilities.

##1、 Preparation before assembly

1. * * Site survey and leveling**

Confirm the levelness of the installation site, remove debris, and make proper drainage plans; If it is an overhead installation, precast concrete piers or steel structure foundations in advance.

2. * * Material inventory**

Check the main body of the finished box, connecting accessories (bolts, sealing strips), photovoltaic system components (photovoltaic panels, energy storage batteries, inverters), door and window accessories, etc. one by one according to the list to ensure that there are no missing or damaged parts.

3. * * Tool preparation**

Equipped with commonly used tools such as wrenches, screwdrivers, drills, and level gauges, there is no need for large lifting equipment (small finished boxes can be manually handled with simple lifting equipment).

##2、 Core assembly steps

1. * * Finished product box is fixed in place**

-Manually or mechanically lift the finished product box to the designated position, and calibrate the levelness and verticality of the box body with a level.

-Fix the box and base with anchor bolts. When multiple boxes are spliced, align the box splicing positions, tighten them with connecting bolts, and fill the gaps with sealing strips to ensure waterproof sealing.

2. Installation of doors, windows, and internal facilities**

-Check the firmness of pre installed doors and windows, and reinforce them if necessary; Install basic circuits such as indoor lighting and sockets (with reserved interfaces for optical storage systems).

-Assemble interior components such as flooring, wall panels, and ceilings according to requirements to quickly complete space creation.

3. Integrated optical storage system**

-Photovoltaic panel installation: Fix the photovoltaic panel on the top of the box with a bracket, adjust the angle to maximize the lighting efficiency.

-Energy storage and inverter connection: Connect energy storage batteries, inverters with photovoltaic panels, and indoor circuits to complete energy conversion and storage; The system supports both grid connected and off grid modes, and can be powered on with just one click.

4. * * Acceptance and debugging**

-Check the sealing of the box (rain test) and structural stability; Debug the light storage system and confirm that the power generation, storage, and supply functions are normal.

-Clean up the installation site, and the finished product can be put into use.

##3、 Assembly advantages

1. * * Efficient and fast * *: Single box assembly only takes * * 2-4 hours * *, and multi box splicing can be completed within 1 day, far faster than traditional construction.

2. * * Easy to operate * *: No need for a professional construction team, ordinary workers can get started with simple training.

3. * * Flexible adaptation * *: Supports single box independent use or multiple box combination expansion, and the optical storage system can be selected as needed to meet different electricity needs.

4. * * Green and environmentally friendly * *: Full process dry construction with no construction waste; The light storage system is self operated and low-carbon and energy-saving.